Constructing A Building? Accurate and Consistent Ribbed TMT Bar is the right choice for you!!!

The construction industry is evolving with time and so is the TMT bar, which is used for imparting strength and safety to the construction. Today, Extra Ductile TMT bars, Double Ribbed TMT bars, corrosion-resistant TMT bars, extra-strong TMT bars and even earthquake resistant TMT bars are the talk of the town.

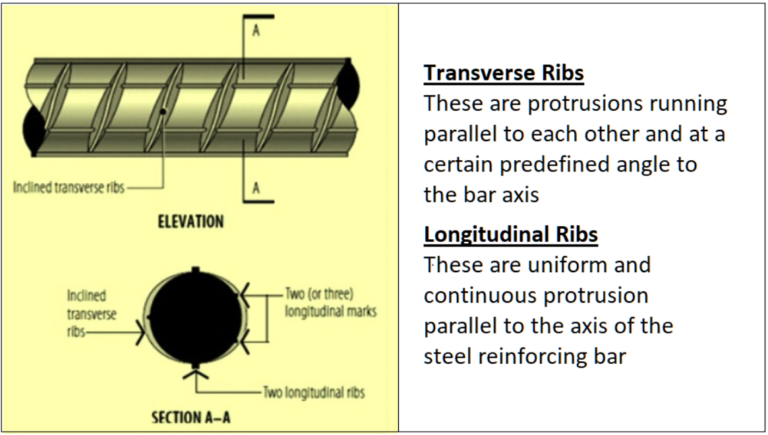

Ribs in a TMT bar

Ribs on a TMT bar increase its bonding with the concrete structure by providing mechanical interlocking and higher surface area. There are two kinds of ribs on a TMT bar, transverse and longitudinal.

Both, the transverse and longitudinal ribs are made as per specifications provided in the BIS 1786: High Strength Deformed Steel Bars and Wires For Concrete Reinforcement – Specification (Fourth Revision)

Ribs in a TMT bar - why?

TMT bars with cross ribbed patterns offer a better gripping which is ideal for construction as its bonding with the concrete is stronger, thereby eliminating the chances of slipping out of the concrete during abnormal stress.

Advantages of Rib in TMT bars

- TMT bars with cross ribbed patterns offer a better gripping which is ideal for construction as its bonding with the concrete is stronger, thereby eliminating the chances of slipping out of the concrete during abnormal stress.

- The structural properties of these bars are better than that of ordinary plain round bars.

- These bars possess excellent bonding properties and hence the end hooks are not required.

- The fatigue life of ribbed bar is reported to be lower than that of smooth bars of identical dimension and grade of steel (Jhamb and MacGregor 1974a)

7 STAR TMT bars, North India’s 1st extra strong TMT bars, offer accurate and consistent rib patterns with a deviation level of maximum 0.2mm. This is achieved using our world-class computer-controlled roller grooving machines and our team of dedicated and experienced engineers.