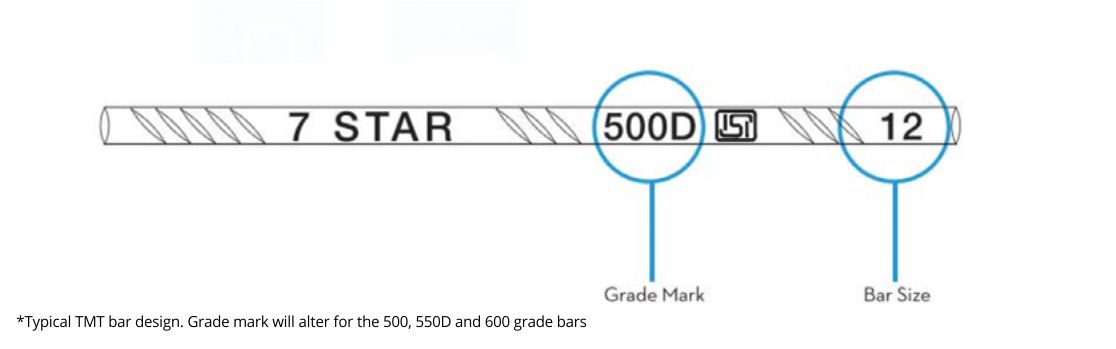

7 STAR 500D

Be it strength, ductility or customisation, our latest offering, 7 STAR 500D grade TMT bar, shines at every parameter.

Get ready for a dazzling display of strength and durability.

The strength of the best global technology

- Created using one of the world’s most trusted TMT manufacturing technology, TEMPCORE. 7 STAR 500D TMT bars draw their strength from the computer-controlled in-line process of hardening and tempering during hot rolling.

- Authorized by Centre De Recherches Mettallurgiques (CRM), Belgium to use their prestigious TEMPCORE process.

- Technical assistance from HEEP&P (Human Engineering for Environmental Products and Production), Germany.

- Certified by Bureau of Indian Standards (BIS) to manufacture Steel Re-bars as per IS: 1786/1985.

- Other global quality certifications like ISO 9001.

Unmatched Performance

HIGHER

BOND

STRENGTH

HIGHER BAND STRENGTH DUCTILITY AND

BEND-ABILITY

HIGHER

TENSILE

STRENGTH

HIGHER CORROSION AND

SEISMIC RESISTANCE

The 7 STAR Advantage

YEARS OF EXPERTISE

PROCESS TECHNOLOGY FROM TEMPCORE, BELGIUM

EXTRA STRENGTH

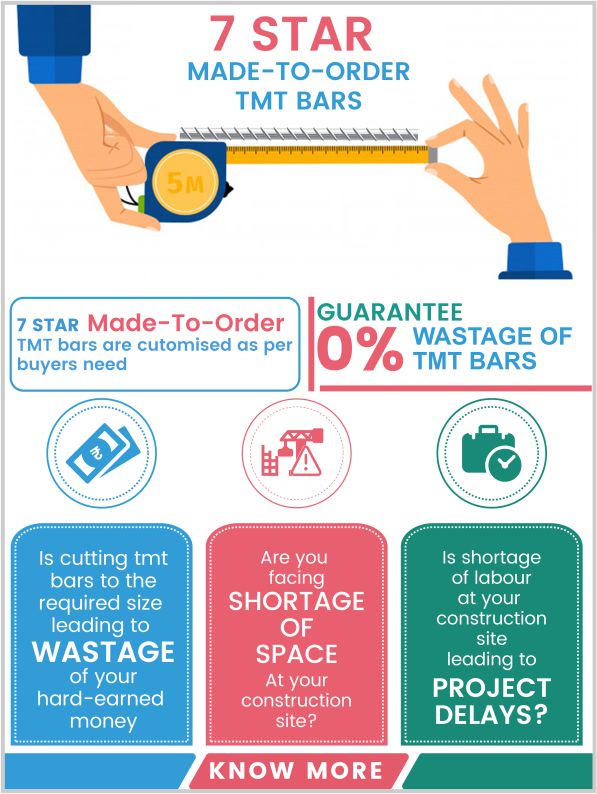

AVAILABLE IN CERTIFIED CUSTOMISED LENGTHS

CERTIFIED

BY BIS

GLOBAL QUALITY

CERTIFICATIONS

AVAILABLE IN

500, 500D, 550D

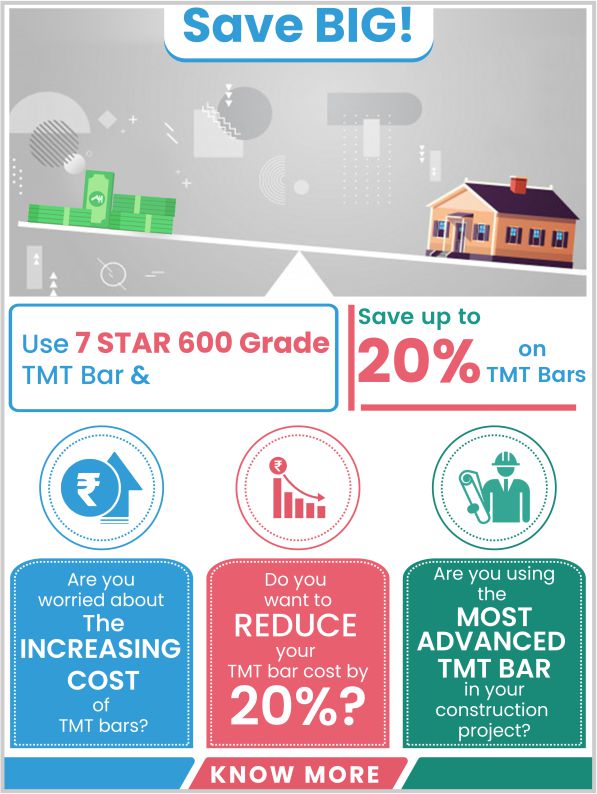

Substantial Savings

*Estimated values based on study by German Institute of Reinforcing Steel

Mechanical Properties

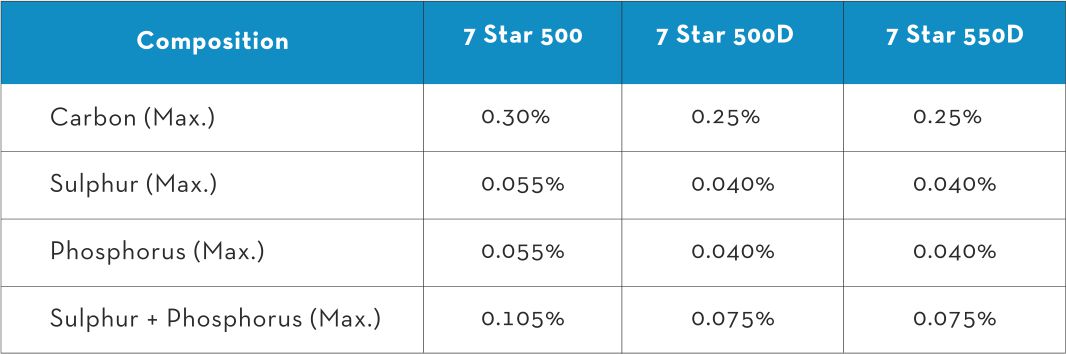

Chemical Properties

TMT Bar Guide*